Slitter rewinder machines are essential in the packaging industry as they provide accuracy and speed for different materials, including those used in the production of plastic bags. This guide is useful to explain the roles and uses of these tools to the newcomers, stressing on their role in production.

Understanding Slitter Rewinder Machines

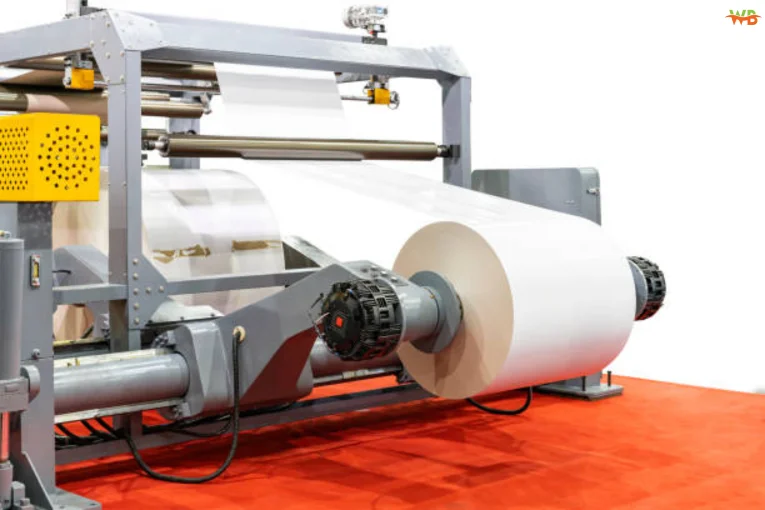

Slitter rewinder machines cut large rolls of material into smaller, more manageable rolls by performing slitting and rewinding operations. Indispensable in the packaging sector especially in the production of plastic bags, they help in cutting the material to the desired width and rewinding for further processing or use. These machines work with different types of materials such as plastic, paper and foil and are therefore useful in manufacturing.

Uses

The main purpose is to precisely cut and rewind the material. The process involves unrolling the large roll of material, scribing it through blades or lasers to make narrower widths and then rolling it into smaller rolls. These machines are highly flexible and can be set to change the blade positions and tension to accommodate various materials and thicknesses in the production of plastic bags to ensure quality.

Advantages

Slitter rewinder machines enhance both the speed of production and the quality of the end product. They enhance precision in cutting, which is important in determining the thickness of the material, which is vital in the production of products of standard sizes. By automating the slitting and rewinding process, they enhance efficiency and minimize the chance of human errors. They also help in the efficient use of materials, and this reduces wastage and, therefore, results in cost cutting. Working with a reliable slitter rewinder machine manufacturer guarantees that your machine is fitted with the most advanced technology and functions for efficiency.

Manufacturing

In plastic bag manufacturing, these machines slit large rolls of plastic film into the required width for various types of bags to achieve the right measurements and quality bags. They work with different materials and thicknesses and are, therefore, very useful in a plastic bag manufacturing machine.

Selecting

The selection of the machine relies on the material type, desired cutting width, and production volume. For integration with existing equipment and specific requirements, it is advisable to consult with a professional slitter rewinder machine manufacturer. Some of the features to consider include the ability to adjust the blade settings, tension, and ease of use to improve your production line.

Thus, slitter rewinder machines play a vital role in the packaging sector, particularly in manufacturing plastic bags. They provide accuracy, speed, and flexibility, which makes them worthwhile assets. Knowing the roles and advantages of slitter rewinder machines, as well as collaborating with a reliable manufacturer, companies can optimize production lines, increase the quality of products, and increase the efficiency of operations.

FAQs About Slitter Rewinder Machines

1. What types of maintenance do slitter rewinder machines require?

- Regular maintenance involves lubricating moving parts, inspecting and replacing blades, and checking tension settings to ensure consistent performance and longevity.

2. Can slitter rewinder machines handle biodegradable materials?

- Yes, many modern machines are capable of handling biodegradable materials, making them suitable for eco-friendly packaging solutions.

3. How does the automation level affect the operation of slitter rewinder machines?

- Higher levels of automation can significantly reduce manual labor, improve precision, and enhance production speed, leading to more efficient operations.

4. What safety features are typically included in slitter rewinder machines?

- They often come with safety features such as emergency stop buttons, safety guards, and automatic shut-off mechanisms to protect operators and prevent accidents.

5. How do they integrate with other packaging machinery?

- They can be integrated with other packaging machinery through automated control systems and compatible interfaces, allowing seamless transitions between different stages of the packaging process.